Core capacities

Check out the core capacities of Softmill built upon ceaseless research and hard work.

Check out the core capacities of Softmill built upon ceaseless research and hard work.

90% of parts were internalized to

flexibly respond to the various demands of consumers.

An integrated management system (ASMS) was constructed in

2022 to provide prompt and accurate follow-up services.

Created a database of customer information and product information to improve work efficiency for issuing servicing

products and sales of materials.

Work efficiency was improved through mobilization of

technicians (agency, freelancer).

We operate a corporate attached technology R&D center for

ongoing product improvement, development of new products,

and development of specialized Korean bakery equipment.

A master confectionery technician at our research center tests

product performance and also conducts R&D on bakery recipes.

First work/study company that signed an agreement with the

Human Resources Development Service of Korea in 2014 and

offers parallel work/learning programs.

We have procured an integrated and specialized HR fostering

system by conducting theoretical/practical education and on-

site work.

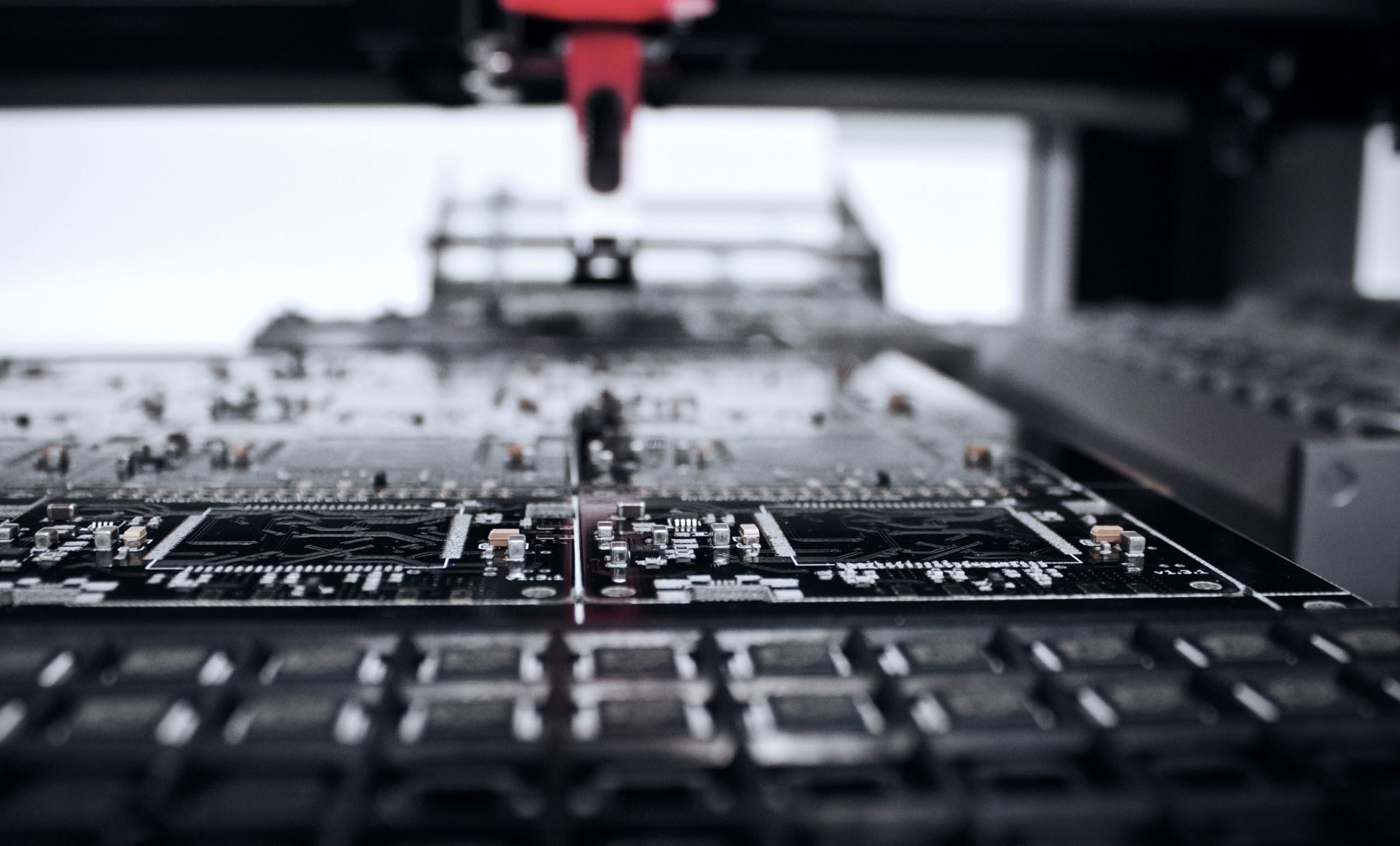

The production process was vertically systemized from parts to end product to

manufacture products with high precision and perfection.

01

Processing work such as precise laser cutting, shearing, and automatic bending for stainless steel, which is a raw material

02

Fully automatic foaming/charging of urethane resin and hardeners using automated machines and metal frames

03

Welding and assembly work using welding rods and spots

04

Assembly of freezer parts and electric parts using high quality Korean and European parts

05

Final inspection and shipping

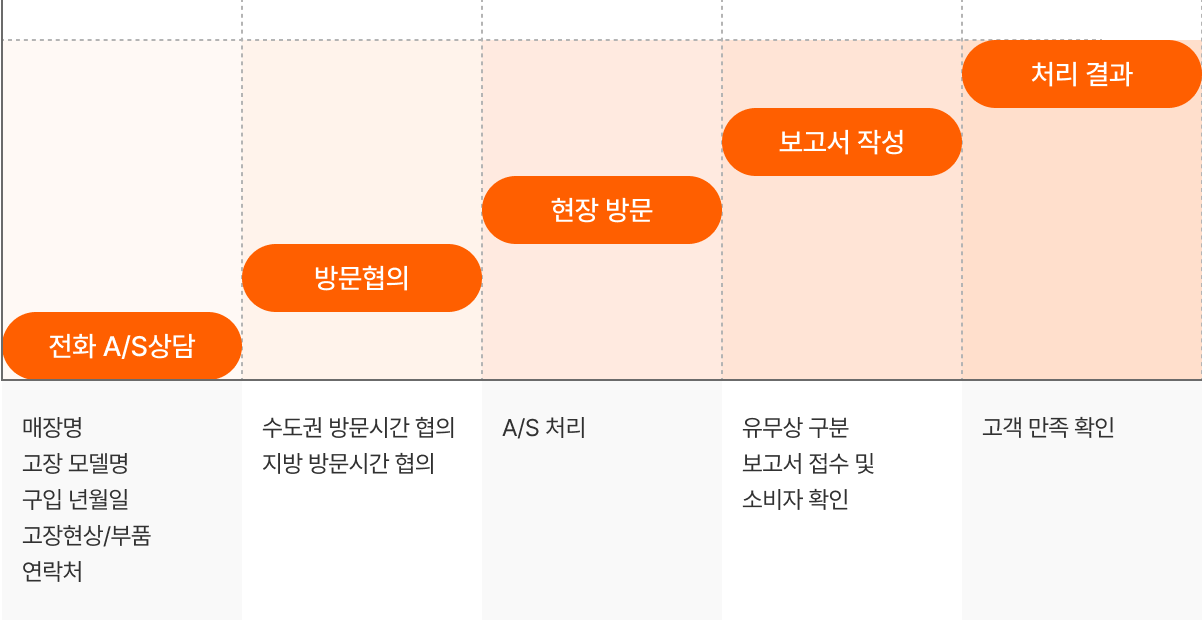

차별화된 A/S서비스

A/S 접수 및 진행 절차

대흥소프트밀은 최상의 A/S를 제공하기 위해 최선을 다하고 있습니다.